Incorporating Flight Regime Recognition into Frequency Sorting and Analysis Processes for the Purposes of Condition Based Maintenance

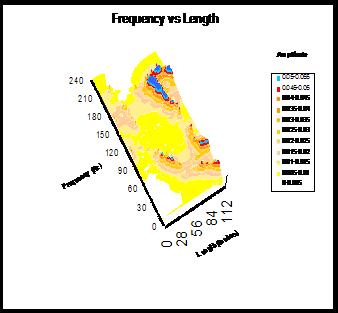

This research identified a methodology for locating nontraditional frequencies of deteriorating rotating components and their locations as related to AH-64 tail rotor components as mounted to the TRDT test stand. For these selected frequencies, this research also illustrated the importance of load monitoring, the influences of shaft misalignment, shaft's imbalances and their effects on vibration signatures and the importance of flight regime recognition. The plan for this research was to devise a way of extracting useful power train information from the test data in order to reduce the amount of false alarms while increasing the ability to detect faults for the last three stages of bearing fault progression.

The desired outcomes were reduced false triggers and misdiagnosis and a reduction in the amount of data monitored by eliminating frequencies that provide no insight on the state of a components health. This also reduced post processing time and storage space required to handle large amounts of data by focusing on frequencies that yielded the most information in reference to a bearings state. Another desired outcome was the incorporation of the affects of loading into the bearing life plot in order to normalize the acquired in flight data. It was also desirable to provide information that improved the ability to create more robust CIs, modification of the existing bearing life algorithms and assist in creating a more successful condition based maintenance program...(read more)

Advertisement copy goes here.

Advertisement copy goes here.

Advertisement copy goes here.

Advertisement copy goes here.